Column-Mounted vs Bracket Cranes: Safer for Plants?

Column-Mounted vs Bracket-Supported Crane Systems: Which Is Safer for Concrete Plants?

Key Takeaways (Right Up Front):

- Column-mounted cranes offer compact layouts and strong centralized support but may require deeper foundations and more frequent inspections.

- Bracket-supported cranes save floor space, allow longer spans, and are ideal for high-capacity concrete plants, but wall integrity and bracket reinforcement are critical.

- Choosing the right system impacts structural safety, operational reliability, long-term maintenance costs, and overall concrete plant productivity.

- Buyers should weigh installation costs vs. lifespan, consider environmental factors like dust and vibration, and plan for future plant expansion.

Introduction

Overhead cranes are the workhorses of concrete plants. They move heavy precast panels, cement silos, and aggregates efficiently—but only if they are set up safely and correctly. How a crane is supported—on columns or wall-mounted brackets—can drastically affect your plant's safety, workflow, and maintenance costs. This guide helps buyers understand the differences and make informed decisions.

Why Structural Support Matters

The way a crane is supported affects how weight and stress are distributed across your building. A poorly chosen system can lead to excessive vibration, sway, or even damage to foundations and walls.

Key points to consider:

- Column-mounted cranes focus the load on vertical structural columns, which often need reinforced foundations.

- Bracket-supported cranes rely on wall-mounted brackets, so wall strength and reinforcement are critical.

- Load distribution, dynamic stress, and building vibration are influenced by the support system, affecting both safety and equipment lifespan.

What This Guide Will Help You With

Before investing in a crane, it's important to understand how each system impacts operational safety, cost, and long-term reliability. Knowing this upfront can save money and prevent headaches down the road.

Here's what this guide covers for buyers:

- Compare column-mounted and bracket-supported cranes in real-world concrete plant scenarios.

- Understand how support type affects installation, safety, and maintenance.

- Make a choice that fits plant layout, lifting needs, and future expansion plans.

Key Takeaways from the Start

Choosing the right support system isn't just about the crane—it's about the plant's overall workflow, safety, and costs. Each system has pros and cons that must be weighed carefully.

Here's what you need to know:

- Column-mounted cranes concentrate the load on structural columns, requiring strong foundations.

- Bracket-supported cranes save floor space but demand reinforced walls capable of carrying heavy loads.

- Operational safety, long-term maintenance, and cost are directly influenced by the support type.

- Environmental factors like concrete dust, moisture, and temperature changes affect each system differently.

- Planning for future plant expansion may make one system more practical than the other.

Introduction

Overhead cranes are the workhorses of concrete plants. They move heavy precast panels, cement silos, and aggregates efficiently—but only if they are set up safely and correctly. How a crane is supported—on columns or wall-mounted brackets—can drastically affect your plant's safety, workflow, and maintenance costs. This guide helps buyers understand the differences and make informed decisions.

Why Structural Support Matters

The way a crane is supported affects how weight and stress are distributed across your building. A poorly chosen system can lead to excessive vibration, sway, or even damage to foundations and walls.

Key points to consider:

- Column-mounted cranes focus the load on vertical structural columns, which often need reinforced foundations.

- Bracket-supported cranes rely on wall-mounted brackets, so wall strength and reinforcement are critical.

- Load distribution, dynamic stress, and building vibration are influenced by the support system, affecting both safety and equipment lifespan.

What This Guide Will Help You With

Before investing in a crane, it's important to understand how each system impacts operational safety, cost, and long-term reliability. Knowing this upfront can save money and prevent headaches down the road.

Here's what this guide covers for buyers:

- Compare column-mounted and bracket-supported cranes in real-world concrete plant scenarios.

- Understand how support type affects installation, safety, and maintenance.

- Make a choice that fits plant layout, lifting needs, and future expansion plans.

Key Takeaways from the Start

Choosing the right support system isn't just about the crane—it's about the plant's overall workflow, safety, and costs. Each system has pros and cons that must be weighed carefully.

Here's what you need to know:

- Column-mounted cranes concentrate the load on structural columns, requiring strong foundations.

- Bracket-supported cranes save floor space but demand reinforced walls capable of carrying heavy loads.

- Operational safety, long-term maintenance, and cost are directly influenced by the support type.

- Environmental factors like concrete dust, moisture, and temperature changes affect each system differently.

- Planning for future plant expansion may make one system more practical than the other.

Overview of Crane Support Systems

Choosing the right crane support system is critical for concrete plants. The support determines not only how much weight your crane can handle, but also how the loads are distributed across columns, walls, and foundations. Here's a closer look at the two most common systems: column-mounted and bracket-supported.

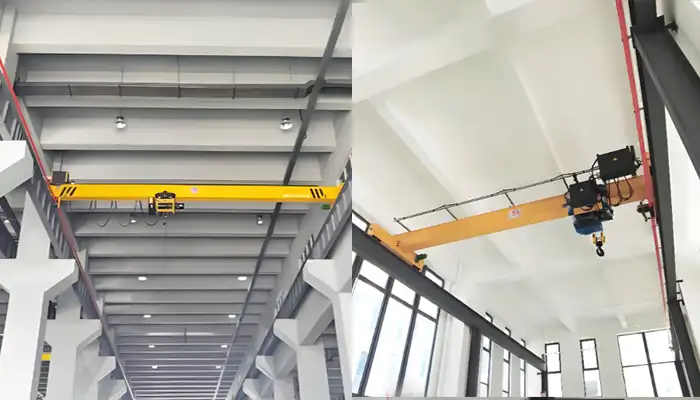

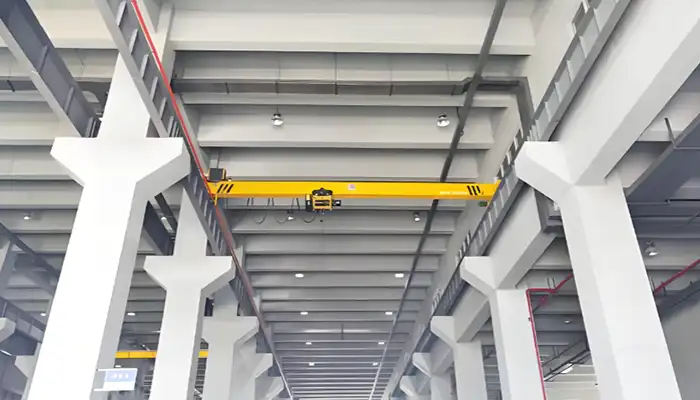

Column-Mounted Crane Systems

Column-mounted cranes are exactly what the name suggests—they rely on vertical structural columns to carry the load. This type of support is straightforward, but it requires careful planning to ensure safety and stability.

Freestanding column mounted crane system

Key features and practical points:

- Definition: These cranes are mounted directly on vertical columns, which bear the full weight of the crane and lifted loads. Columns are often reinforced to handle both dynamic and static loads.

- Advantages: The design offers a compact footprint, keeping floor space mostly clear. Load-bearing is centralized, making it easier to manage heavy lifts in a confined area.

- Typical Applications: Ideal for small-to-medium concrete plants, workshops with limited floor space, or facilities where expansion is unlikely. Column-mounted systems work best when the foundation can handle concentrated loads and vibration is minimal.

Column-mounted systems are practical when you need strong, reliable support without complex wall reinforcement. However, they may require deeper foundations and more frequent inspections to maintain safety.

Bracket-Supported Crane Systems

Bracket-supported cranes take a different approach. Instead of relying on floor columns, they use wall-mounted brackets or reinforced beams to hold the crane rails. This changes the way the load is distributed and can free up valuable floor space.

Key features and practical points:

- Definition: Rails are attached to wall-mounted brackets or structural beams, which transfer the load to the building's walls. Proper wall reinforcement is essential to handle heavy materials safely.

- Advantages: This system allows for longer spans and reduces obstruction on the factory floor. It is especially useful for high-capacity plants where crane travel distance is significant.

- Typical Applications: Common in tall batching towers, large precast plants, and high-capacity concrete facilities where floor space is limited and long-span lifting is needed.

Bracket-supported systems are excellent for plants with high ceilings or long travel requirements. The key consideration is wall strength—weak or poorly reinforced walls can lead to structural issues or frequent maintenance.

Safety Comparison

Safety is the most important factor when choosing a crane system for a concrete plant. The type of support affects not only how much weight the crane can lift but also how the building responds to repeated loads, vibrations, and environmental stress. Let's break down the key safety considerations into structural, operational, and maintenance aspects.

Structural Safety

The foundation and structural support of a crane are the first line of defense against accidents. A crane's stability depends on how well the columns or walls carry the weight of both the crane and the materials being lifted.

- Column-mounted cranes: These systems rely on strong, reinforced foundations. If the foundation is weak or uneven, the columns can deflect under heavy loads, reducing safety and causing long-term wear.

- Bracket-supported cranes: Safety depends on wall strength and proper bracket reinforcement. Weak walls or poorly anchored brackets can lead to sway or structural damage over time.

- Additional Considerations: Always account for load distribution, vibration resistance, and stress points along the crane runway. Even small miscalculations can increase maintenance needs or reduce lifespan.

Operational Safety

How a crane performs during everyday lifting tasks directly impacts plant safety. Poorly supported cranes can sway, limit clearance, or fail under unexpected loads.

- Ensure there is enough clearance for large material lifts, especially with precast panels, silos, or aggregate bins.

- Evaluate the system's resistance to sway and deflection, particularly during high-frequency operations or long travel distances.

- Confirm that overload handling and emergency shutdown mechanisms are reliable. This prevents accidents when operators exceed recommended load limits or equipment malfunctions.

Operational safety is about reducing risks to workers and materials during regular plant activity. Even a small misalignment or excessive sway can cause serious disruptions or damage.

Maintenance Safety

A crane that is difficult to inspect or maintain can become a hidden risk. Dust, concrete residue, and moisture in concrete plants accelerate wear, so accessibility and routine checks are critical.

- Check inspection accessibility for beams, columns, brackets, and rails. If critical points are hard to reach, small issues can turn into major problems.

- Plan for the frequency of inspections and long-term structural monitoring, including load-bearing capacity tests and bracket checks.

- Consider the impact of concrete dust, moisture, and residue, which can corrode or wear crane components over time, affecting safety and reliability.

Maintenance safety is about foresight. A crane system that's easy to inspect and maintain reduces downtime and ensures safer operation over the life of the plant.

Cost Comparison

Cost is often a deciding factor when selecting a crane support system. But it's not just the price tag of the crane itself—structural support, installation, and long-term maintenance all add up. Understanding the full cost picture helps buyers avoid surprises and plan for the life of the crane.

Initial Investment

The type of support system significantly affects upfront costs. Column-mounted systems usually require reinforced foundations, while bracket-supported systems need wall strengthening or structural beams.

- Column-mounted cranes: Require strong, reinforced foundations to carry concentrated loads. Excavation, concrete pouring, and reinforcement can make the initial cost higher.

- Bracket-supported cranes: Walls must be evaluated and reinforced if needed, which may involve adding steel brackets or supporting beams. This can sometimes be cheaper than deep foundations but depends on the building's condition.

Installation Complexity

Installation time and labor affect both cost and operational downtime. A more complex installation can delay production and increase overall expenses.

- Column-mounted cranes require precise alignment of columns and foundations. Any misalignment can affect crane travel and load handling.

- Bracket-supported cranes require careful wall assessment and secure attachment of brackets. The installation team must ensure that the wall can safely carry the crane's full load along the entire span.

- Downtime during installation must be factored into total project cost, especially in high-capacity plants where production time is critical.

Long-Term Costs

Even after installation, the support system influences ongoing expenses. Maintenance, inspections, and potential structural upgrades can add significant cost over the crane's lifespan.

- Column-mounted cranes may require foundation monitoring and occasional reinforcement over time, particularly in high-frequency lifting plants.

- Bracket-supported cranes need regular checks of wall anchors and brackets to prevent fatigue or loosening.

- Dust, concrete residue, and environmental conditions can affect both systems, increasing maintenance frequency.

Practical Example

Consider a 20-ton crane in a medium-sized concrete plant:

- A column-mounted system might have higher upfront foundation costs but lower wall reinforcement costs.

- A bracket-supported system may reduce foundation work but require careful wall strengthening and ongoing bracket inspections.

- Depending on plant layout, labor availability, and future expansion plans, either system can be cost-effective if planned properly.

By evaluating initial investment, installation, and long-term maintenance, buyers can choose a support system that balances cost and reliability while minimizing operational interruptions.

Long-Term Reliability

A crane's support system isn't just about lifting capacity today—it determines how well your equipment performs over years of heavy use. Reliability affects safety, maintenance schedules, and overall plant efficiency. Understanding how fatigue, stress, and environmental conditions impact your crane is essential for long-term planning.

Fatigue and Stress Over Time

Repeated lifting cycles put continuous stress on columns, brackets, and rails. Over time, even small deflections or vibrations can weaken structural components if not addressed.

- Column-mounted cranes: Concentrated loads on columns can cause fatigue at the base and connections, especially in high-frequency operations. Regular structural inspections are essential to detect early signs of wear.

- Bracket-supported cranes: Brackets and wall anchors bear the weight along the span. Fatigue can occur at multiple points, including the bracket welds or bolts, so reinforcement and monitoring are crucial.

Environmental Factors

Concrete plants are harsh environments. Dust, moisture, and temperature changes can accelerate wear and reduce reliability if support structures are not properly protected.

- Humidity and moisture can corrode steel components, especially wall brackets and column bases.

- Concrete dust can accumulate on moving parts and support structures, increasing friction and stress over time.

- Temperature fluctuations can expand or contract metal, causing small movements that add up to structural fatigue over years.

Expected Lifespan

The lifespan of a crane system depends on design, materials, and maintenance practices. Choosing the right support type can extend operational life and reduce unexpected downtime.

- Column-mounted cranes: Tend to have longer lifespans if foundations are well-designed and regularly inspected.

- Bracket-supported cranes: Can last equally long with properly reinforced walls and ongoing bracket inspections, but weak wall structures can shorten their life.

Downtime and Replacement Planning

Long-term reliability also affects production planning. Unexpected failures can halt operations and increase repair costs.

- Schedule regular inspections for both systems to catch issues before they become critical.

- Factor in potential downtime for maintenance, component replacement, or reinforcement.

- Plan for gradual wear in high-frequency lifting environments rather than waiting for a major failure.

By considering fatigue, environmental conditions, and lifespan, concrete plant operators can choose a crane support system that remains safe and reliable for years, minimizing downtime and unexpected expenses.

Buyer Considerations

Choosing the right crane support system is not just about the equipment itself—it's about how it fits into your plant's operations, safety requirements, and long-term plans. A support system that works perfectly in one plant may be a poor fit in another if layout, lifting needs, or future expansion aren't considered.

Plant Layout and Floor Space Constraints

Every concrete plant has unique space requirements. The available floor area, ceiling height, and overall plant layout influence which crane system will work best.

- Column-mounted cranes take up floor space around the columns, which may limit vehicle or equipment movement.

- Bracket-supported cranes free up floor space but require strong walls along the entire crane span.

- Consider workflow, material flow, and accessibility for both workers and vehicles when evaluating crane placement.

Crane Lifting Capacity, Frequency, and Span Requirements

Not all cranes are used the same way. Some plants lift heavy precast panels occasionally, while others handle aggregates continuously throughout the day.

- Determine the maximum load your crane will lift regularly and occasionally.

- Assess lifting frequency—high-frequency operations create more stress on columns, brackets, and rails.

- Span requirements affect both support type and rail design; longer spans may favor bracket-supported systems if floor space is limited.

Compliance with Local Building Codes and Safety Standards

Safety regulations vary by region, and compliance is essential to avoid fines and ensure worker safety.

- Check local building codes for column or wall load-bearing requirements.

- Ensure the crane support system meets concrete plant safety standards and inspection protocols.

- Confirm that both system types (column-mounted or bracket-supported) can handle environmental loads like wind, dust, and temperature changes.

Future Plant Expansion and Adaptability

Concrete plants often evolve over time. Choosing a system that can adapt saves money and prevents major reconstruction later.

- Column-mounted cranes are easier to extend in height but may require foundation modifications for higher loads.

- Bracket-supported cranes can span longer distances but require wall reinforcement if you increase crane capacity.

- Consider future equipment, additional cranes, or workflow changes when selecting a support system.

Total Cost of Ownership (TCO) Analysis

Initial purchase cost is just the beginning. Long-term expenses like maintenance, inspections, structural upgrades, and downtime must be considered.

- Compare installation, reinforcement, and foundation costs for both systems.

- Factor in routine maintenance and inspection schedules.

- Include potential downtime costs in TCO calculations, especially for high-capacity or high-frequency plants.

By considering layout, lifting needs, compliance, future growth, and total cost, buyers can select a crane support system that balances safety, efficiency, and long-term reliability.

Case Study

Real-world examples help illustrate how column-mounted and bracket-supported crane systems perform in concrete plants. These cases highlight both advantages and limitations, giving buyers practical insights for decision-making.

Column-Mounted 15-Ton Crane in a Mid-Size Precast Plant

Column-mounted cranes are often chosen for mid-sized precast plants where floor space is somewhat limited but strong foundation support is available.

Key points from this installation:

- Advantages: The crane offered a compact footprint and centralized load-bearing. Columns were reinforced to handle repeated lifting of heavy panels, which ensured stable operation. The setup allowed precise material positioning for small-to-medium spans.

- Limitations: Installation required careful foundation design and excavation, which increased upfront costs. During high-frequency operations, the columns showed minor vibration, requiring periodic inspection and tightening of connections. Expansion options were limited due to fixed column placement.

Bracket-Supported 25-Ton Crane in a High-Capacity Batching Plant

Bracket-supported cranes are suitable for larger plants with taller ceilings and longer crane spans. This 25-ton installation demonstrates the system's flexibility and potential challenges.

Lessons learned from this installation:

- Advantages: The bracket system allowed a long-span crane without interfering with floor operations. It minimized column obstructions, enabling better movement of vehicles and materials. The system handled heavy aggregate and cement silos efficiently.

- Challenges: Wall reinforcement was critical. Any weaknesses in the wall caused minor deflections that needed adjustment during initial operation. Regular inspection of brackets and anchor bolts became essential to maintain safety and reliability. Planning for future capacity increases required additional wall strengthening.

These examples show that while both systems are effective, the choice depends on plant size, lifting capacity, available floor space, and long-term operational plans. Column-mounted cranes work well for compact setups with strong foundations, while bracket-supported cranes shine in tall, high-capacity plants but require careful wall design and maintenance planning.

Conclusion

Selecting the right crane support system can make or break operations in a concrete plant. Both column-mounted and bracket-supported systems work well, but each comes with unique requirements, advantages, and limitations. The best choice depends on your plant layout, lifting needs, and long-term plans.

Column-Mounted Cranes

Column-mounted systems are ideal when you have strong foundations and limited floor space. They provide centralized support for precise material handling, but they also require careful maintenance.

- Centralized load-bearing keeps crane operation stable.

- Foundations must be reinforced and regularly inspected.

- Less flexibility for future plant expansion without major structural modifications.

Bracket-Supported Cranes

Bracket-supported systems excel in high-capacity plants and setups where long spans are needed. They free up floor space and allow smoother material flow but demand strong, well-reinforced walls.

- Saves floor space by reducing column obstructions.

- Requires reinforced walls and secure brackets to prevent deflection.

- Needs regular inspection of anchors and brackets to maintain safety.

Key Takeaways for Buyers

When deciding between these systems, focus on long-term performance and safety:

- Ensure the support system can handle maximum loads and frequent operations safely.

- Evaluate both initial investment and long-term maintenance costs.

- Consider environmental factors such as concrete dust, humidity, and temperature changes.

- Plan for future expansion and changes in plant layout.

Practical Steps Before Finalizing Your Crane

Before making the purchase:

- Conduct a pre-installation assessment of foundations, walls, and crane layout.

- Verify the supplier's experience, certifications, and references in concrete plants.

- Check compliance with local building codes and safety standards to prevent downtime or accidents.

In short, a careful evaluation of plant needs, structural requirements, and long-term reliability will help you choose a crane system that keeps your operations safe, efficient, and ready for years to come.

Column-Mounted vs Bracket-Supported Crane Systems: FAQ for Concrete Plants

This guide helps buyers, engineers, and plant managers understand the differences, costs, safety, and long-term reliability of column-mounted and bracket-supported crane systems in concrete plants.

What are the differences between column-mounted and bracket-supported crane systems in concrete plants?

Column-mounted cranes are supported directly by vertical structural columns. The load is concentrated through the columns to the foundation. Bracket-supported cranes, on the other hand, rely on rails mounted on wall brackets or reinforced beams, spreading the load along the walls rather than through floor columns.

- Column-mounted systems: compact footprint, concentrated load, ideal for medium spans and smaller plants.

- Bracket-supported systems: longer spans, walls carry load, better for tall structures and large batching plants.

- Structural considerations: columns need strong foundations, while brackets require reinforced walls and proper anchoring.

Which system provides better structural safety and stability for heavy material handling?

Both systems can be safe if designed correctly, but each has specific strengths depending on the plant environment.

- Column-mounted cranes provide high stability if foundations are properly designed for dynamic and static loads.

- Bracket-supported cranes reduce floor interference and distribute load along walls, which can be advantageous in high-capacity plants.

- Critical factors: load distribution, vibration resistance, sway control, and stress points must be assessed before installation.

How do installation and maintenance costs compare between the two systems?

Costs vary based on the building structure, crane capacity, and design complexity.

- Column-mounted systems: higher upfront costs due to strong foundations, but easier access for maintenance.

- Bracket-supported systems: may require less foundation work but higher engineering for wall reinforcement; maintenance access can be more challenging.

- Long-term considerations: inspections, wear monitoring, and structural reinforcement costs should be included in the total cost of ownership.

Which crane support system is more reliable long-term in a concrete plant environment?

Reliability depends on proper design, installation, and environmental conditions.

- Column-mounted cranes: reliable over time if foundations and columns are designed for the specific loads and dynamic forces.

- Bracket-supported cranes: effective for high-capacity, long-span applications but depend heavily on wall strength and quality of reinforcement.

- Environmental factors like concrete dust, humidity, and temperature variations should be considered for both systems to prevent corrosion or wear.

What should buyers check before selecting a crane system for concrete batching, precast, or aggregate handling?

Choosing the right system requires a detailed assessment of both operational needs and building constraints.

- Evaluate lifting capacity, crane frequency, and span requirements based on current and future plant operations.

- Check structural compatibility with the workshop or plant building: column foundations or wall strength.

- Consider long-term reliability, maintenance accessibility, and safety standards.

- Review total cost of ownership, including installation, inspection, and potential upgrades.